Welding Work Clamp Definition

Clamp definition is a device designed to bind or constrict or to press two or more parts together so as to hold them firmly.

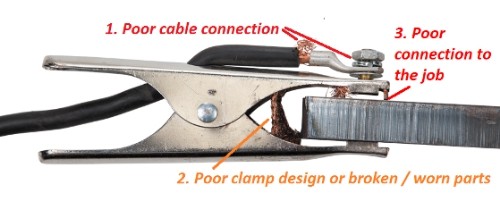

Welding work clamp definition. Remember that the work lead cables or cables should be neatly organized not strung about haphazardly. The welding circuit is energized by welding voltage. The work lead clamp may be attached directly to the workpiece or to the fixture holding the workpiece. Heat can build up in the work clamp reducing welding efficiency.

How to use clamp in a sentence. Two axis clamp the two axis clamps hold together two tubes or rods at an angle. A person will receive a shock if they become the electrical path across the welding circuit. Welding seems to make the components joint stronger than a clamp but in reality clamps make them equally stronger.

Welding cables should. The work lead connection may vary with the welding process amperage or application. Work clamps the work clamp must be the correct size for the current being used and it must clamp tightly to the material. Designed for the high torque loads applied by an impact wrench the dimide clamp is a reliable clamp that is perfect for squeezing parts together preventing part slippage removing the clamp.

I personally prefer using a clamp to welding. A be wrapped around the body to distribute the weight. The clamp should be touched occasionally to find out if it is getting hot. The thickness of the objects do not need to be the same.

A may have power losses that should be ignored b reduces welding efficiency c must not clamp too tightly to the material d should be carefully touched occasionally to determine if it is hot. The voltage is reduced by the transformer in the electric welding machine the current is increased and the electric arc. Welding circuit shock hazards utilizing proper grounding in the welding environment is a good practice but it does not remove all possibility of electrical shock. A variation on the two axis clamp is the 90 degree clamp which has specific purpose of holding materials together at a right angle.

A few points that explain the importance of a well maintained work clamp for any arc welding process. It s just a ground clamp whats the big deal. It gives me the freedom to change the parts whenever i need like changing the muffler is super easy if i use exhaust clamp rather than welding it. Power losses in the work clamp are often overlooked.

These clamps are often fixed onto welding tables.