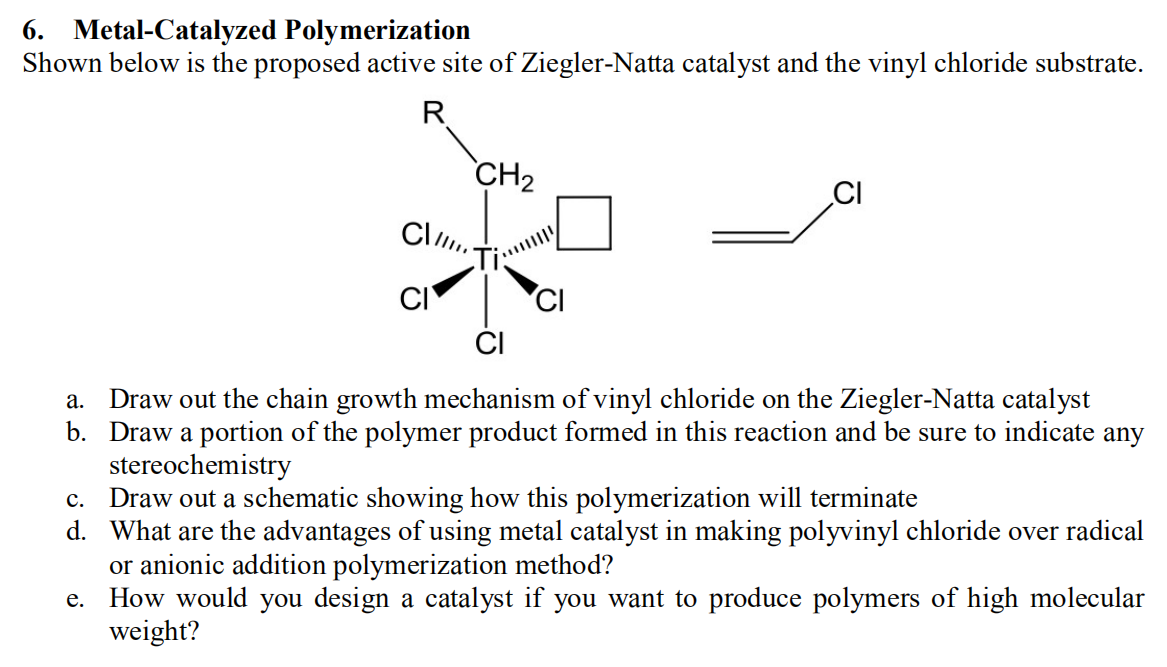

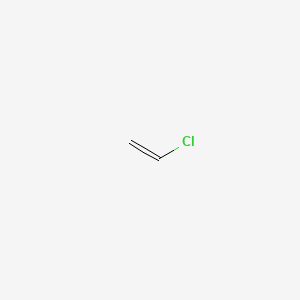

Vinyl Chloride Polymerization Mechanism

Atom in the vinyl chloride molecule is mainly responsible for the three different modes of addition of a n w mono mer lu1i on the polymer chain during propagation.

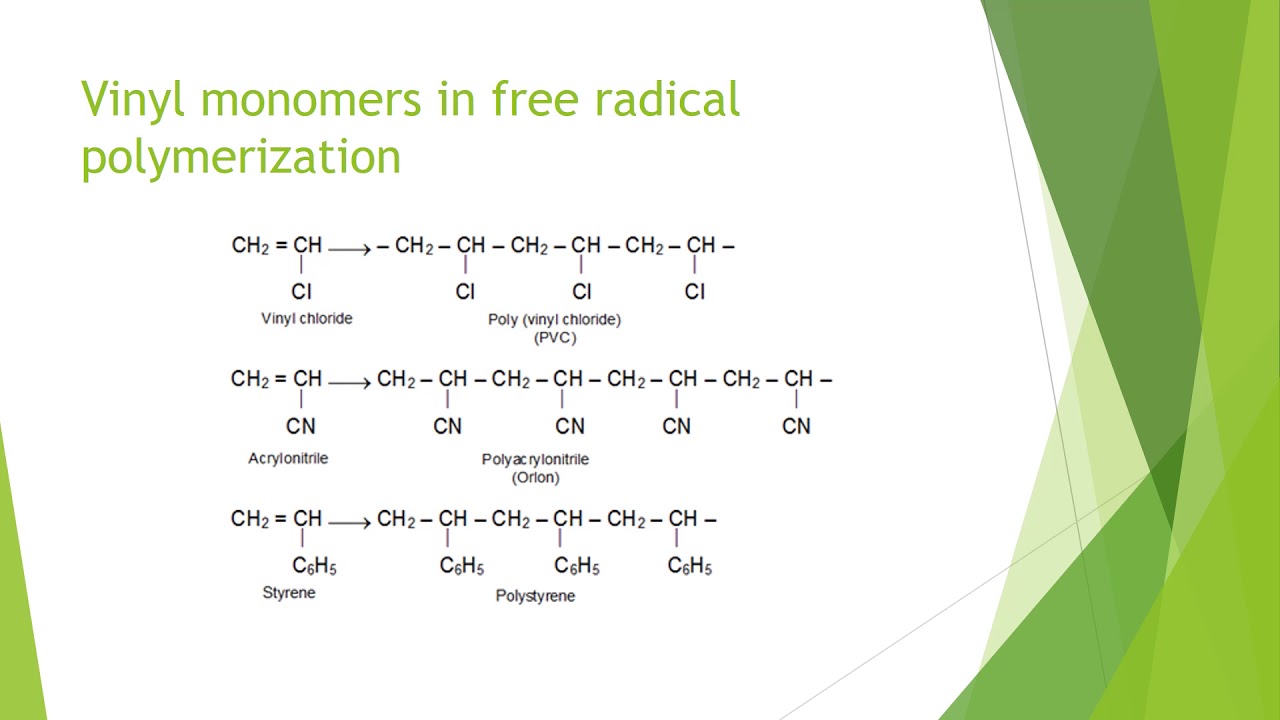

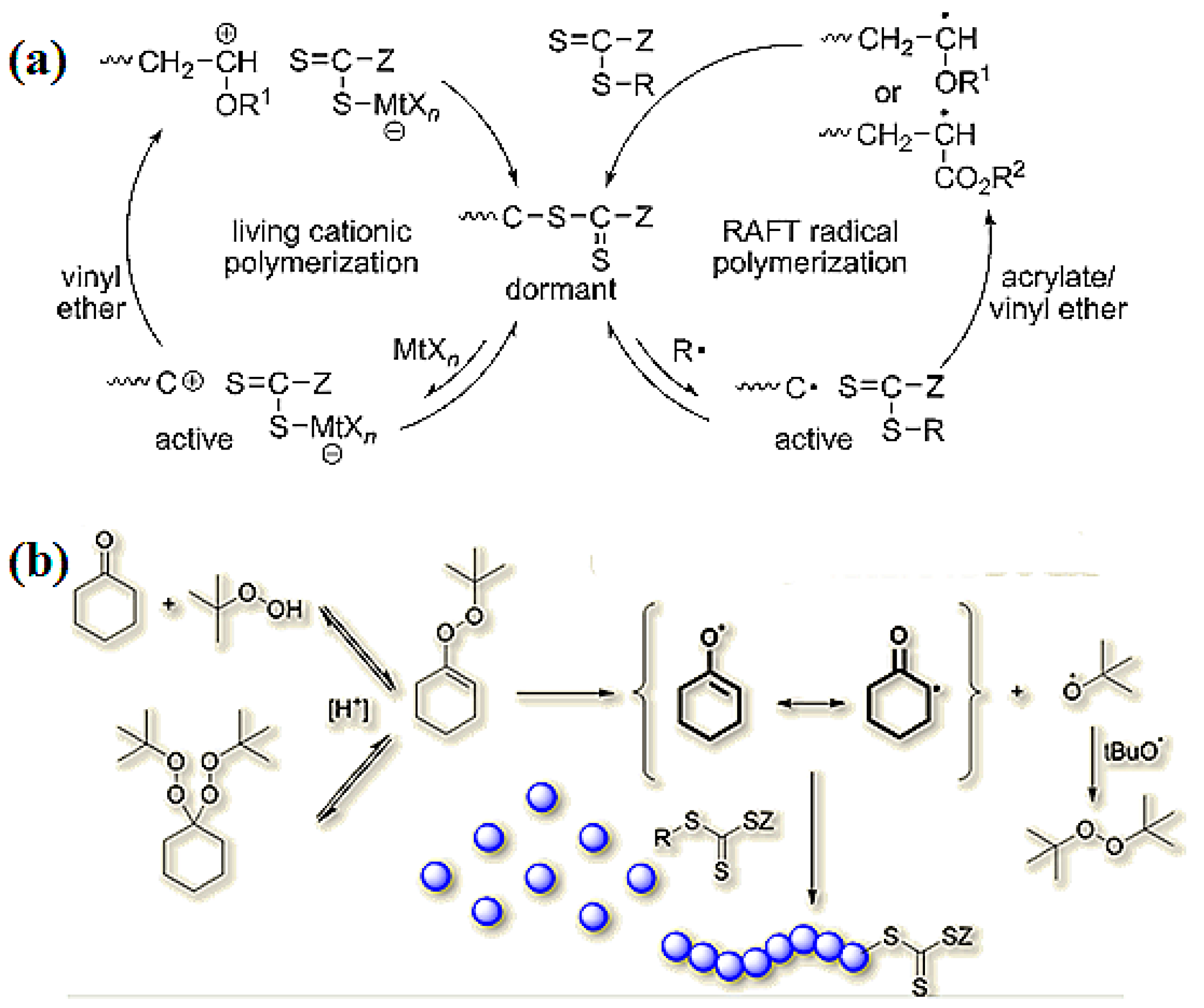

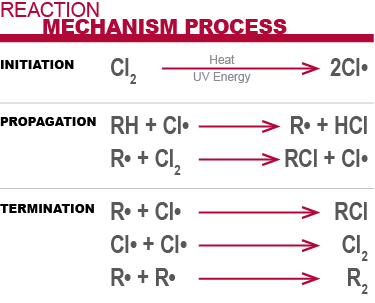

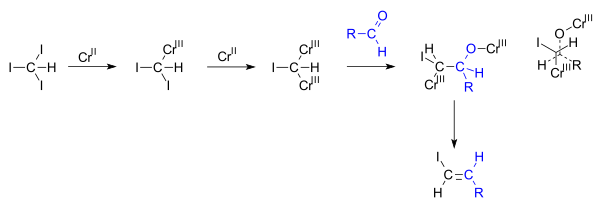

Vinyl chloride polymerization mechanism. Vc vc α d 1 vc β β d 2 and vc d 3 were used to study the reactivities of the hydrogen atoms in the polymerization and the β hydrogen atoms contributed to the chain transfer. Polymerization of vinyl chloride vc was studied. Following its generation the initiating free radical adds nonradical monomer units thereby growing the polymer chain. Free radicals can be formed by a number of different mechanisms usually involving separate initiator molecules.

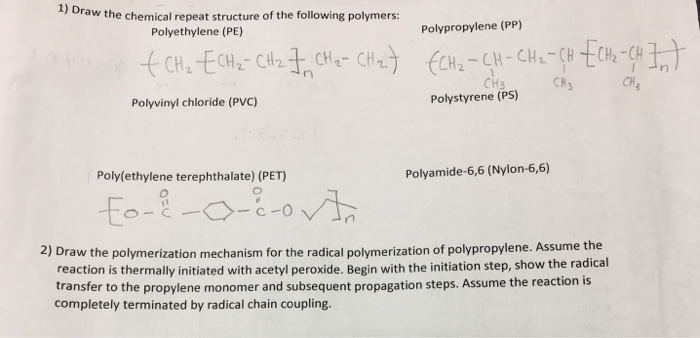

Free radical polymerization frp is a method of polymerization by which a polymer forms by the successive addition of free radical building blocks. This polymerisation reaction proceeds by a free radical mechanism. The process can be resolved into five discrete stages each of which presents a unique environment for the interaction of the systems parameters. The process can be resolved into five discrete stages each of which presents a unique.

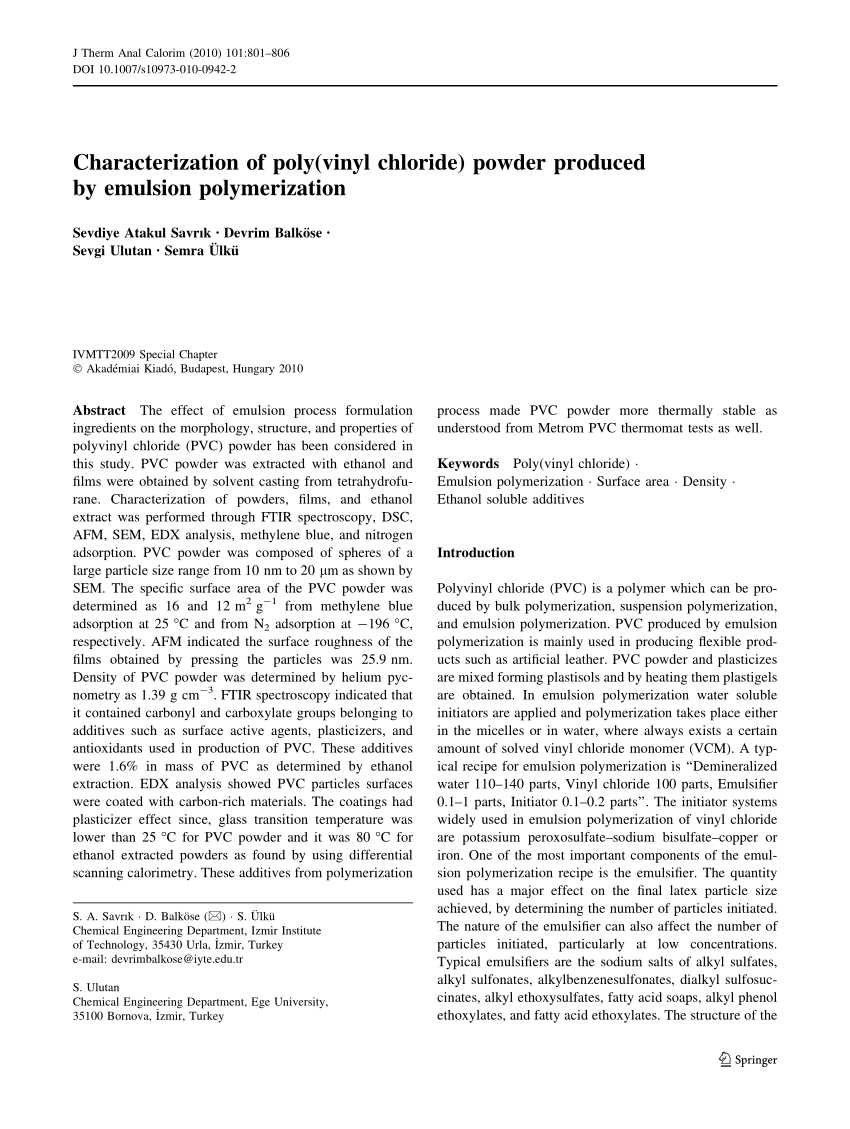

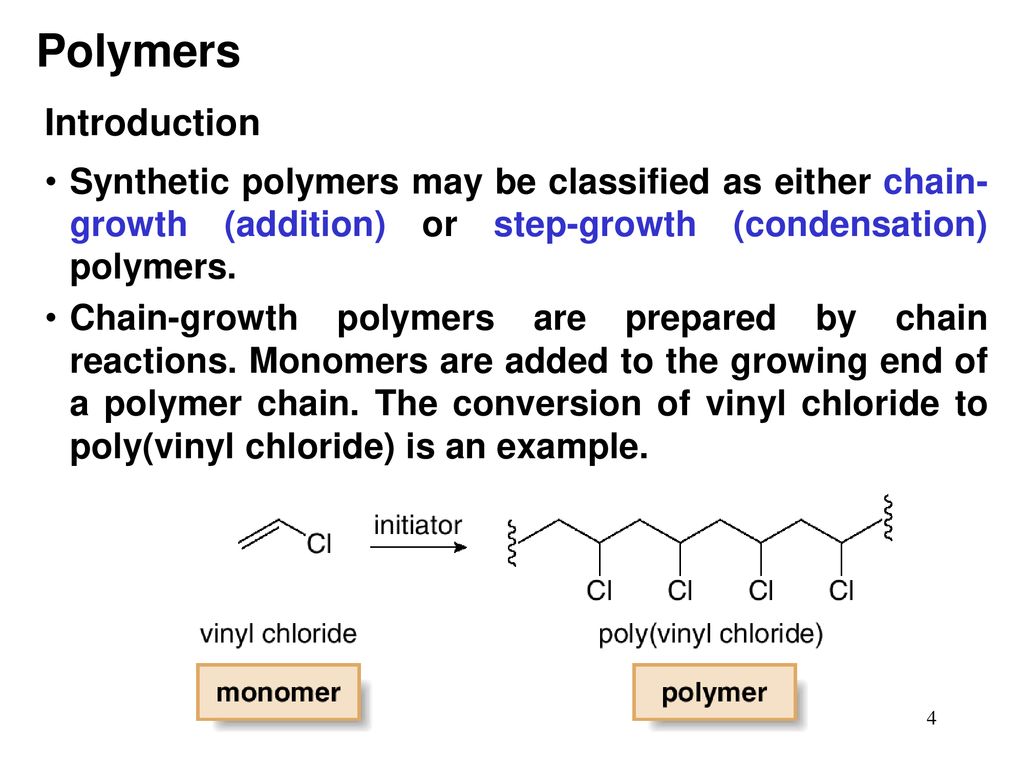

Vinyl chloride plus others. Return to level four directory. Abstract relevant mechanisms involved in the heterogeneous free radical polymerization of vinyl chloride have been identified including elemen tary chemical reactions. Polyvinyl chloride is produced in an addition polymerisation reaction using the chloroethene vinyl chloride monomer.

Natural evolution of hcl from vc occurred in the polymerization. The three diffe rent modes are known as head io tail head to head and tail tp tai1 structure as shown in figure 6. An overall mechanistic scheme for the suspension polymerization of vinyl chloride is presented. Abstract an overall mechanistic scheme for the suspension polymerization of vinyl chloride is presented.

Vinyl chloride liquid is fed to polymerization reactors where it is converted from a monomeric vcm to a polymeric pvc. Physical phenomena of polyvinylchloride parti cle formation and reactant species distributions inphas sduring poly merization. Additives are used to modify the properties of polyvinyl chloride to make it more useful. Polyvinyl chloride is a white rigid quite brittle solid.

The final product of the polymerization process is pvc in either a flake or pellet form. Chemical and physical methods were used to observe irregular structures such as branching double bonds and head to head or tail to tail addition and also to confirm the relation. A new mechanism not yet confirmed is suggested to explain a reported enhancement in the chloromethyl branch concentration of poly vinyl chloride pvc prepared at high conversions of monomer. Now for free radical polymerization of ethacrylic acid.